Trailer Light Wiring Harness Diagram

A trailer light wiring harness is a set of wires that connects the lights on your trailer to your tow vehicle. It is important to have a properly wired harness to ensure that your trailer lights are working properly and that you are compliant with the law. There are a few different types of trailer light wiring harnesses available, so it is important to choose one that is compatible with your trailer and tow vehicle.

Here are the steps on how to create a trailer light wiring harness diagram:

- Gather your materials. You will need:

- A roll of wire

- Wire strippers

- Electrical tape

- A crimp tool

- A fuse holder

- A fuse

- A ground wire

Determine the type of wiring harness you need. There are two main types of trailer light wiring harnesses: flat 4-pin and round 7-pin. Flat 4-pin harnesses are the most common type and are used for basic lighting functions, such as turn signals, brake lights, and tail lights. Round 7-pin harnesses are used for more complex lighting functions, such as running lights, reverse lights, and brake controllers.Measure and cut the wire. You will need to measure and cut the wire to the appropriate length for your trailer. Be sure to leave some extra wire at the ends for splicing.Strip the ends of the wire. Use wire strippers to strip the ends of the wire about 1/2 inch.Crimp the connectors onto the wire. Use a crimp tool to crimp the connectors onto the ends of the wire. Be sure to crimp the connectors securely.Connect the wires to the fuse holder. Connect the positive wire to the fuse holder and the negative wire to the ground wire.Install the fuse. Insert the fuse into the fuse holder.Test the wiring harness. Connect the wiring harness to your trailer and tow vehicle and test the lights to make sure they are working properly.

Here are some benefits of using a trailer light wiring harness diagram:

- It will help you to wire your trailer lights correctly.

- It will save you time and money by preventing you from having to troubleshoot electrical problems.

- It will help you to stay compliant with the law.

Trailer light wiring harness diagrams are a valuable tool for anyone who tows a trailer. By following the steps outlined in this article, you can create a diagram that will help you to wire your trailer lights correctly and safely.

Trailer Light Wiring Harness

A trailer light wiring harness is a crucial component that ensures the proper functioning of your trailer’s lighting system. It connects the electrical system of your tow vehicle to the lights on your trailer, allowing them to operate safely and legally. Here are six key aspects to consider when dealing with trailer light wiring harnesses:

- Compatibility: Choosing a wiring harness compatible with your trailer and tow vehicle is essential for proper functionality.

- Wire gauge: The thickness of the wires in the harness determines their current-carrying capacity, which must match the electrical requirements of your trailer lights.

- Circuit protection: Fuses or circuit breakers protect the wiring harness from electrical overloads and short circuits.

- Grounding: A proper ground connection ensures a complete electrical circuit and prevents electrical malfunctions.

- Durability: The wiring harness should be constructed with durable materials to withstand harsh conditions and environmental factors.

- Installation: Following the correct installation procedures and using appropriate connectors is crucial for a reliable and safe electrical connection.

These aspects are interconnected and equally important for the effective operation of your trailer light wiring harness. Proper compatibility ensures the harness matches the specific electrical requirements of your trailer and tow vehicle. Adequate wire gauge and circuit protection prevent electrical hazards, while proper grounding completes the electrical circuit and enhances safety. Durability ensures the harness can withstand the rigors of towing, and correct installation guarantees a reliable connection. By considering these essential aspects, you can ensure the safe and efficient functioning of your trailer’s lighting system.

Compatibility

Compatibility between the wiring harness, trailer, and tow vehicle is paramount for the proper functioning of the trailer light wiring harness. The electrical systems of different vehicles vary, and using an incompatible harness can lead to electrical malfunctions, safety hazards, and legal non-compliance. For instance, a trailer designed for a 7-pin connector may not function correctly if connected to a tow vehicle with a 4-pin harness. Choosing a compatible wiring harness ensures that the electrical signals are transmitted correctly, allowing the trailer lights to operate as intended.

The importance of compatibility extends beyond basic functionality. Incompatible harnesses can cause electrical overloads, leading to blown fuses, damaged wiring, or even fires. Overloaded circuits can also affect other electrical components in the tow vehicle or trailer, compromising safety. Furthermore, using an incompatible harness may result in lighting issues, such as flickering lights, dim bulbs, or complete electrical failure, posing a significant safety hazard, especially during nighttime driving or inclement weather conditions.

Understanding the compatibility aspect of trailer light wiring harnesses is crucial for ensuring the safe and legal operation of your trailer. By choosing a wiring harness specifically designed for your trailer and tow vehicle, you can prevent electrical problems, safety hazards, and legal repercussions. This understanding empowers you to make informed decisions when selecting and installing a trailer light wiring harness, contributing to the overall reliability and functionality of your towing system.

Wire gauge

The wire gauge, which refers to the thickness of the wires in the trailer light wiring harness, plays a crucial role in ensuring the safe and efficient operation of your trailer’s lighting system. The current-carrying capacity of the wires must align with the electrical demands of the trailer lights to prevent electrical hazards and maintain optimal performance.

Insufficient wire gauge can lead to several issues. When the wires are too thin, they may overheat due to excessive electrical current, potentially causing damage to the wiring harness, trailer lights, or even the tow vehicle’s electrical system. Overheated wires can lead to melted insulation, short circuits, and even fires, posing significant safety risks.

Conversely, using wires with a thicker gauge than necessary may increase the cost and weight of the wiring harness without providing any additional benefits. Selecting the appropriate wire gauge is therefore essential to balance safety, performance, and cost-effectiveness.

Understanding the connection between wire gauge and trailer light wiring harness empowers you to make informed decisions during installation or replacement. By choosing a wiring harness with the correct wire gauge, you can ensure that your trailer lights receive the necessary electrical power without overloading the circuit, preventing potential hazards and ensuring reliable illumination.

Circuit protection

Circuit protection is a crucial aspect of any electrical system, including trailer light wiring harnesses. It safeguards the wiring harness and connected components from potential damage caused by electrical overloads and short circuits, ensuring the reliable operation of trailer lights and preventing safety hazards.

- Prevention of electrical fires: Electrical overloads occur when too much current flows through the wiring harness, which can lead to overheating and potential fires. Fuses or circuit breakers act as safety switches, interrupting the electrical current if it exceeds a safe threshold, preventing the risk of electrical fires.

- Protection against short circuits: Short circuits happen when an electrical current finds an unintended path, causing a sudden surge of electricity. This can damage the wiring harness, trailer lights, or even the tow vehicle’s electrical system. Fuses or circuit breakers quickly break the circuit, preventing the spread of damage and potential electrical shocks.

- Isolation of faulty circuits: When a fault occurs in one part of the trailer light wiring harness, fuses or circuit breakers isolate the affected circuit, preventing the fault from spreading to other parts of the system. This allows for easier troubleshooting and repairs, minimizing downtime and ensuring the continued operation of the remaining lights.

- Compliance with safety regulations: Many regions have regulations requiring the use of fuses or circuit breakers in trailer light wiring harnesses to ensure electrical safety. Using a wiring harness equipped with proper circuit protection demonstrates compliance with these regulations and helps prevent potential legal issues.

By understanding the connection between circuit protection and trailer light wiring harnesses, you can appreciate the importance of using a wiring harness with adequate safety features. Fuses or circuit breakers act as the first line of defense against electrical hazards, protecting your trailer, tow vehicle, and passengers from potential harm. Investing in a

wiring harness with reliable circuit protection ensures peace of mind and contributes to the overall safety and reliability of your towing system.

Grounding

Grounding is a fundamental aspect of any electrical system, including trailer light wiring harnesses. It provides a path for electrical current to flow back to the source, completing the circuit and ensuring the proper functioning of electrical components. A proper ground connection is essential for several reasons:

- Circuit completion: Grounding completes the electrical circuit, allowing current to flow from the power source, through the lights, and back to the source. Without a proper ground, the circuit is incomplete, and the lights will not function.

- Voltage stability: Grounding helps stabilize the voltage in the electrical system. When the system is properly grounded, voltage fluctuations are minimized, ensuring that the lights receive a consistent power supply.

- Electrical safety: Grounding provides a safe path for excess electrical current to flow away from the system. In the event of an electrical fault, grounding prevents the buildup of dangerous voltage levels, reducing the risk of electrical shocks and fires.

- Compliance with regulations: Many regions have regulations requiring proper grounding of electrical systems, including trailer light wiring harnesses. Using a wiring harness with a proper ground connection demonstrates compliance with these regulations and helps prevent potential legal issues.

Understanding the connection between grounding and trailer light wiring harnesses underscores the importance of using a wiring harness with a reliable ground connection. Proper grounding ensures the completion of the electrical circuit, voltage stability, electrical safety, and compliance with regulations. By investing in a wiring harness with a well-designed grounding system, you can ensure the safe, reliable, and legal operation of your trailer’s lighting system.

Durability

Durability is a crucial aspect of trailer light wiring harnesses, as they are exposed to various harsh conditions and environmental factors that can affect their performance and longevity. Using durable materials in the construction of the wiring harness ensures that it can withstand these challenges and provide reliable operation over time.

- Resistance to moisture and corrosion: Wiring harnesses are often subjected to moisture and humidity, which can lead to corrosion and damage to the wires and connectors. Durable materials, such as waterproof insulation and corrosion-resistant metals, protect the harness from these elements, ensuring reliable electrical connections.

- Protection against UV rays: Prolonged exposure to ultraviolet rays from the sun can degrade the materials used in the wiring harness, making them brittle and susceptible to damage. UV-resistant materials, such as heat-stabilized plastics and coatings, help prevent this degradation, extending the lifespan of the harness.

- Resistance to abrasion and impact: Wiring harnesses can experience physical stress, such as abrasion from rubbing against other components or impact from road debris. Durable materials, such as abrasion-resistant sheathing and reinforced connectors, protect the harness from these hazards, ensuring its integrity and functionality.

- Temperature extremes: Trailer light wiring harnesses must withstand extreme temperatures, both high and low. Durable materials, such as heat-resistant insulation and cold-resistant plastics, prevent the harness from melting or becoming brittle in extreme conditions, ensuring reliable operation in all climates.

By understanding the connection between durability and trailer light wiring harnesses, you can appreciate the importance of using a wiring harness constructed with durable materials. Durability ensures the harness can withstand the rigors of towing, exposure to the elements, and physical stress, providing long-lasting and reliable performance. Investing in a durable wiring harness contributes to the overall safety, reliability, and longevity of your trailer’s lighting system.

Installation

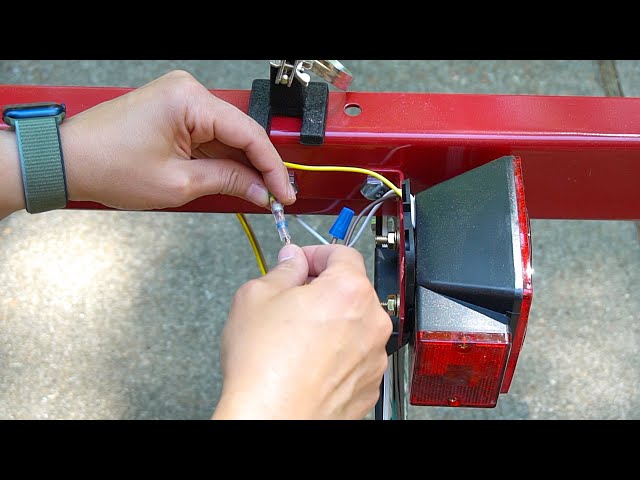

Proper installation is paramount for the safe and reliable operation of a trailer light wiring harness. It ensures that the electrical connections between the tow vehicle and the trailer are secure, preventing potential electrical hazards and ensuring optimal performance of the trailer lights.

Using appropriate connectors is essential for a secure and weather-resistant connection. These connectors are designed to withstand the vibrations and environmental conditions encountered during towing, preventing loose connections and electrical malfunctions. Inadequate or improper connectors can lead to intermittent lighting, voltage drops, and even complete electrical failure, compromising safety.

Correct installation procedures involve following the manufacturer’s instructions and industry best practices. This includes using the proper tools, applying the correct torque to electrical connections, and securing the wiring harness to prevent damage from abrasion or snagging. Incorrect installation can result in loose connections, shorts, or even fires, posing significant safety risks.

Understanding the importance of proper installation and appropriate connectors empowers you to ensure the reliability and safety of your trailer’s lighting system. By following the correct procedures and using high-quality components, you can prevent electrical problems, maintain optimal lighting performance, and contribute to the overall safety of your towing experience.

A trailer light wiring harness is an essential component that connects the electrical system of a tow vehicle to the lights on a trailer, enabling them to function properly and safely. It is a set of wires, connectors, and other electrical components that provide a reliable electrical connection between the two vehicles.

Trailer light wiring harnesses are crucial for ensuring that the trailer’s lights, including brake lights, turn signals, and running lights, are visible to other drivers on the road. They play a vital role in enhancing visibility and communication, promoting safety and preventing accidents. Moreover, they facilitate the proper functioning of additional electrical features on the trailer, such as interior lighting or charging systems.

Historically, trailer light wiring harnesses were relatively simple, consisting of a few basic wires and connectors. However, with the advancement of technology and the increasing complexity of trailer systems, modern wiring harnesses have become more sophisticated, incorporating additional features and enhanced safety measures. They often include integrated modules, relays, and surge protectors to safeguard against electrical overloads and short circuits.

Trailer Light Wiring Harness FAQs

Trailer light wiring harnesses play a critical role in ensuring the safety and functionality of your towing system. Here are answers to some frequently asked questions about trailer light wiring harnesses:

Question 1: What is the purpose of a trailer light wiring harness?

Answer: A trailer light wiring harness provides the electrical connection between the tow vehicle and the trailer, enabling the trailer’s lights to function properly. It ensures that the trailer’s brake lights, turn signals, running lights, and other electrical components receive power and operate as intended.

Question 2: What are the different types of trailer light wiring harnesses available?

Answer: The two main types of trailer light wiring harnesses are flat 4-pin and round 7-pin harnesses. Flat 4-pin harnesses are commonly used for basic lighting functions, such as turn signals, brake lights, and tail lights. Round 7-pin harnesses provide additional connections for more complex lighting functions, such as running lights, reverse lights, and brake controllers.

Question 3: How do I choose the right trailer light wiring harness for my needs?

Answer: The type of trailer light wiring harness you need depends on the specific lighting requirements of your trailer. Consider the number and type of lights on your trailer, as well as any additional electrical features you may want to use. It is always recommended to consult the manufacturer’s instructions or a qualified electrician for guidance.

Question 4: How do I install a trailer light wiring harness?

Answer: Installing a trailer light wiring harness requires some electrical knowledge and skills. It is important to follow the manufacturer’s instructions carefully and ensure that all connections are secure. If you are not comfortable performing the installation yourself, it is advisable to seek assistance from a qualified electrician.

Question 5: What are some common problems associated with trailer light wiring harnesses?

Answer: Some common problems include loose connections, damaged wires, and faulty connectors. These issues can lead to intermittent or complete failure of the trailer lights. Regular inspection and maintenance of the wiring harness can help prevent these problems and ensure the continued proper functioning of your trailer’s lighting system.

Understanding these FAQs can help you make informed decisions about selecting, installing, and maintaining a trailer light wiring harness. By ensuring that your trailer’s lighting system is properly wired and functioning correctly, you contribute to the safety and visibility of your towing setup.

For more in-depth information or if you encounter specific issues with your trailer light wiring harness, consult the manufacturer’s documentation or seek professional assistance from an electrician or automotive technician.

Conclusion

Trailer light wiring harnesses play a vital role in ensuring the safety and functionality of your towing system. They provide the electrical connection between the tow vehicle and the trailer, enabling the trailer’s lights to operate properly and communicate with other vehicles on the road. Understanding the purpose, types, selection, installation, and maintenance of trailer light wiring harnesses is crucial for responsible and safe towing practices.

By choosing the right wiring harness for your needs and ensuring its proper installation and maintenance, you can contribute to the visibility and safety of your trailer on the road. Regular inspection and troubleshooting can help prevent problems and ensure continued reliable operation of your trailer’s lighting system. Remember, a well-maintained trailer light wiring harness is essential for safe and legal towing.

Youtube Video: