Ishikawa Fishbone Cause-and-Effect Diagram

An Ishikawa fishbone cause-and-effect diagram, also called a fishbone diagram, is a visual tool used to identify and analyze the root causes of a problem. It is named after its creator, Kaoru Ishikawa, a Japanese quality control expert. Fishbone diagrams are often used in manufacturing and process improvement, but can be applied to any problem-solving situation.

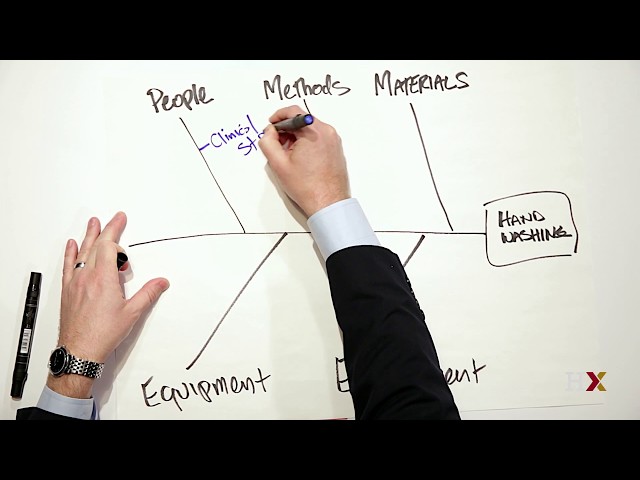

To create a fishbone diagram, start by drawing a horizontal line. Then, draw a vertical line perpendicular to the horizontal line at the left end. This will form the “backbone” of the fishbone diagram.

Next, identify the main problem or issue that you are trying to solve. Write this in a box at the right end of the horizontal line.

Then, brainstorm all of the possible causes of the problem. Write each cause in a box on a diagonal line that branches off from the backbone.

Once you have identified all of the possible causes, group them into categories. Common categories include:

- People

- Processes

- Equipment

- Materials

- Environment

Once you have grouped the causes into categories, you can begin to analyze them to identify the root causes of the problem.

Fishbone diagrams can be a helpful tool for identifying and analyzing the root causes of a problem. They are easy to create and can be used to solve a wide variety of problems.

Benefits of using a fishbone diagram:

- Helps to identify the root causes of a problem

- Provides a visual representation of the problem and its potential causes

- Can be used to identify and prioritize solutions

- Can help to improve communication and collaboration between team members

Tips for creating a fishbone diagram:

- Define the problem or issue that you are trying to solve.

- Brainstorm all of the possible causes of the problem.

- Group the causes into categories.

- Analyze the causes to identify the root causes of the problem.

- Develop and implement solutions to address the root causes of the problem.

Fishbone diagrams are a powerful tool that can be used to identify and solve problems. By following the steps outlined above, you can create a fishbone diagram that will help you to improve your quality and efficiency.

Key Aspects of Ishikawa Fishbone Cause-and-Effect Diagram

An Ishikawa fishbone cause-and-effect diagram is a visual tool used to identify and analyze the root causes of a problem. It is named after its creator, Kaoru Ishikawa, a Japanese quality control expert.

- Visual: Fishbone diagrams are a visual representation of a problem and its potential causes.

- Logical: Fishbone diagrams are based on the logical assumption that all problems have a root cause.

- Systematic: Fishbone diagrams provide a systematic approach to problem-solving.

- Collaborative: Fishbone diagrams can be used to facilitate collaboration between team members.

- Versatile: Fishbone diagrams can be used to solve a wide variety of problems.

- Effective: Fishbone diagrams are an effective tool for identifying and solving problems.

These six key aspects make Ishikawa fishbone cause-and-effect diagrams a valuable tool for problem-solving. They can be used to improve quality, efficiency, and safety in any industry.

For example, a fishbone diagram can be used to identify the root causes of a quality problem on a manufacturing line. Once the root causes have been identified, corrective actions can be taken to prevent the problem from recurring.

Fishbone diagrams can also be used to identify the root causes of safety problems. Once the root causes have been identified, preventive measures can be taken to prevent accidents from happening.

Ishikawa fishbone cause-and-effect diagrams are a powerful tool that can be used to solve problems and improve processes. By understanding the key aspects of fishbone diagrams, you can use them effectively to improve your organization.

Visual

The visual nature of fishbone diagrams is one of their key strengths. They provide a clear and concise overview of a problem and its potential causes, making it easy to identify and analyze the root causes.

- Components: Fishbone diagrams are made up of a horizontal line (the backbone) and several diagonal lines (the branches). The backbone represents the problem or issue being analyzed, while the branches represent the potential causes.

- Examples: Fishbone diagrams can be used to analyze a wide variety of problems, such as quality problems, safety problems, and process problems.

- Implications: The visual nature of fishbone diagrams makes them easy to understand and communicate. This can be helpful when working with teams or stakeholders who may not be familiar with the problem-solving process.

The visual nature of fishbone diagrams makes them a valuable tool for problem-solving. They can help to identify and analyze the root causes of a problem, and they can be used to communicate the problem and its potential solutions to others.

Logical

The logical assumption that all problems have a root cause is a fundamental principle of the Ishikawa fishbone cause-and-effect diagram. This assumption is based on the belief that every problem is caused by a specific set of factors, and that by identifying and addressing these factors, the problem can be solved.

The logical nature of fishbone diagrams makes them a powerful tool for problem-solving. By forcing users to identify the root causes of a problem, fishbone diagrams help to ensure that the problem is solved effectively and permanently.

For example, a manufacturing company may be experiencing a problem with product defects. A fishbone diagram can be used to identify the root causes of the problem, such as poor quality materials, inadequate training, or faulty equipment. Once the root causes have been identified, the company can take steps to address them and prevent the problem from recurring.

The logical assumption that all problems have a root cause is a key component of the Ishikawa fishbone cause-and-effect diagram. This assumption helps to ensure that fishbone diagrams are an effective tool for problem-solving.

Systematic

The systematic approach of Ishikawa fishbone cause-and-effect diagrams is a key factor in their effectiveness. This approach ensures that all potential causes of a problem are identified and analyzed in a logical and organized manner.

- Components: Fishbone diagrams are made up of a series of steps that guide users through the problem-solving process. These steps include identifying the problem, brainstorming potential causes, categorizing the causes, and analyzing the causes to identify the root cause.

- Examples: Fishbone diagrams can be used to solve a wide variety of problems, such as quality problems, safety problems, and process problems. In each case, the systematic approach of the fishbone diagram helps to ensure that the problem is solved effectively and permanently.

- Implications: The systematic approach of fishbone diagrams makes them a valuable tool for any organization that is serious about solving problems and improving processes.

The systematic approach of Ishikawa fishbone cause-and-effect diagrams is one of their key strengths. This approach ensures that all potential causes of a problem are identified and analyzed in a logical and organized manner, which increases the likelihood of finding the root cause and solving the problem permanently.

Collaborative

The collaborative nature of Ishikawa fishbone cause-and-effect diagrams is a key factor in their effectiveness. Fishbone diagrams can be used to bring together team members from different departments or disciplines to work together to identify and solve problems.

For example, a manufacturing company may be experiencing a problem with product defects. A fishbone diagram can be used to bring together team members from engineering, production, and quality control to work together to identify the root causes of the problem. This collaborative approach can help to ensure that all potential causes of the problem are identified and that the problem is solved effectively and permanently.

The collaborative nature of fishbone diagrams is also beneficial for organizations that are implementing continuous improvement programs. Fishbone diagrams can be used to identify and solve problems that are preventing the organization from achieving its goals. By working together to identify and solve problems, team members can help the organization to improve its processes and achieve its goals more quickly.

The collaborative nature of Ishikawa fishbone cause-and-effect diagrams is a key component of their effectiveness. Fishbone diagrams can be used to bring together team members from different departments or disciplines to work together to identify and solve problems. This collaborative approach can help to ensure that all potential causes of a problem are identified and that the problem is solved effectively and permanently.

Versatile

The versatility of Ishikawa fishbone cause-and-effect diagrams is one of their key strengths. Fishbone diagrams can be used to solve problems in any industry or sector.

- Quality problems: Fishbone diagrams can be used to identify and solve quality problems, such as defects, errors, and complaints.

- Safety problems: Fishbone diagrams can be used to identify and solve safety problems, such as accidents, injuries, and near misses.

- Process problems: Fishbone diagrams can be used to identify and solve process problems, such as delays, bottlenecks, and inefficiencies.

- Product development problems: Fishbone diagrams can be used to identify and solve product development problems, such as design flaws, functionality issues, and customer complaints.

The versatility of fishbone diagrams makes them a valuable tool for any organization that is serious about solving problems and improving processes. Fishbone diagrams can be used to identify and solve problems in any area of an organization, from manufacturing to customer service to product development.

Effective

The effectiveness of Ishikawa fishbone cause-and-effect diagrams is due to several factors. First, fishbone diagrams provide a visual representation of a problem and its potential causes. This visual representation makes it easy to see the relationships between different factors and to identify the root cause of a problem.

Second, fishbone diagrams are based on the logical assumption that all problems have a root cause. This assumption helps to ensure that fishbone diagrams are focused on identifying the underlying causes of a problem, rather than just treating the symptoms.

Third, fishbone diagrams provide a systematic approach to problem-solving. The step-by-step process of creating a fishbone diagram helps to ensure that all potential causes of a problem are identified and analyzed.

As a result of these factors, Ishikawa fishbone cause-and-effect diagrams are an effective tool for identifying and solving problems. Fishbone diagrams can be used to solve problems in any industry or sector, and they can be used by teams or individuals.

For example, a manufacturing company may be experiencing a problem with product defects. A fishbone diagram can be used to identify the root causes of the problem, such as poor quality materials, inadequate training, or faulty equipment. Once the root causes have been identified, the company can take steps to address them and prevent the problem from recurring.

Fishbone diagrams can also be used to solve problems in other areas, such as customer service, product development, and process improvement. In each case, the fishbone diagram can help to identify the root causes of the problem and develop effective solutions.

The effectiveness of Ishikawa fishbone cause-and-effect diagrams has been proven in a wide variety of applications. Fishbone diagrams are a valuable tool for any organization that is serious about solving problems and improving processes.

An Ishikawa fishbone cause-and-effect diagram, also known as a fishbone diagram, is a visual tool used to identify and analyze the potential causes of a problem or issue.

This diagram was developed by Kaoru Ishikawa, a Japanese quality control expert, in the 1960s. Fishbone diagrams are widely used in various industries, including manufacturing, healthcare, and business, to improve quality and efficiency.

The fishbone diagram is shaped like the skeleton of a fish, with the main problem or issue represented by the head of the fish. The branches of the fishbone represent the potential causes of the problem, which are typically categorized into several major categories, such as:

- People

- Processes

- Equipment

- Materials

- Environment

- Methods

By brainstorming and identifying all the potential causes, teams can better understand the root cause of the problem and develop effective solutions to address it.

FAQs on Ishikawa Fishbone Cause-and-Effect Diagram

The Ishikawa fishbone cause-and-effect diagram, also known as a fishbone diagram, is a visual tool used to identify and analyze the potential causes of a problem or issue. Developed by Kaoru Ishikawa in the 1960s, it is widely used in various industries to improve quality and efficiency.

Question 1: What are the benefits of using a fishbone diagram?

Answer: Fishbone diagrams offer several benefits, including identifying the root cause of a problem, providing a visual representation for easy analysis, facilitating collaboration among team members, and improving problem-solving efficiency.

Question 2: What are the key elements of a fishbone diagram?

Answer: A fishbone diagram consists of a main problem statement represented by the head of the fish, branches representing potential causes categorized into major categories such as people, processes, equipment, materials, environment, and methods.

Question 3: How do you create a fishbone diagram?

Answer: To create a fishbone diagram, start by defining the problem statement. Then, brainstorm and categorize potential causes into the major categories. Draw the diagram with the problem at the head and the causes as branches, ensuring a logical flow of relationships.

Question 4: What are the common mistakes to avoid when using a fishbone diagram?

Answer: Common mistakes include focusing on symptoms rather than root causes, overlooking potential causes, failing to categorize causes effectively, and making the diagram too complex or cluttered.

Question 5: What are the limitations of a fishbone diagram?

Answer: Fishbone diagrams may not be suitable for highly complex problems or situations where there are numerous interconnected causes. Additionally, the effectiveness of the diagram relies on the accuracy and completeness of the identified causes.

Question 6: How can fishbone diagrams be used in different industries?

Answer: Fishbone diagrams are versatile and can be applied in various industries. They are commonly used in manufacturing for quality control, in healthcare for root cause analysis of medical errors, and in business for process improvement and problem-solving.

Summary:

Ishikawa fishbone cause-and-effect diagrams are a valuable tool for identifying and analyzing the root causes of problems. By following best practices and avoiding common pitfalls, you can effectively use fishbone diagrams to improve problem-solving, enhance quality, and drive continuous improvement in various industries.

Transition to the next article section:

In the next section, we will explore the applications of fishbone diagrams in different industries and discuss advanced techniques for effective problem-solving.

Conclusion

The Ishikawa fishbone cause-and-effect diagram has proven to be a powerful tool for identifying and analyzing the root causes of problems in various industries. Its visual representation, logical structure, and systematic approach make it an effective problem-solving methodology.

By understanding the key principles, elements, and applications of fishbone diagrams, organizations can leverage this technique to improve quality, enhance efficiency, and drive continuous improvement. Embracing the collaborative nature of fishbone diagrams fosters a culture of teamwork and knowledge sharing, leading to more effective problem-solving outcomes.

As organizations navigate increasingly complex challenges, the Ishikawa fishbone cause-and-effect diagram will continue to be a valuable tool for identifying underlying causes, developing targeted solutions, and achieving operational excellence.

Youtube Video: