Piping and Instrumentation Diagram (P&ID)

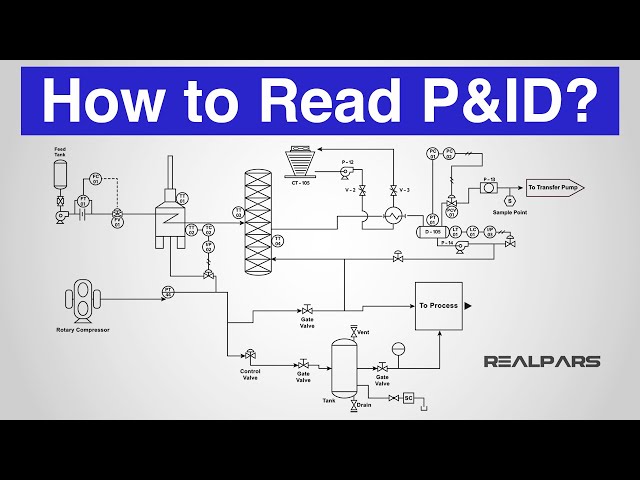

A Piping and Instrumentation Diagram (P&ID) is a detailed diagram that shows the piping, instrumentation, and equipment in a process plant. P&IDs are used to design, construct, and operate process plants, and they are essential for ensuring the safe and efficient operation of these plants.

There are many different types of P&IDs, but all of them share some common features. These features include:

- A legend that explains the symbols used in the diagram

- A title block that contains information about the diagram, such as the project name, the date, and the author

- A process flow diagram that shows the flow of process fluids through the plant

- A piping diagram that shows the piping that connects the equipment in the plant

- An instrumentation diagram that shows the instrumentation that is used to control the process

P&IDs are created using a variety of software programs. These programs allow the user to create a diagram that is both accurate and easy to read.

P&IDs are an essential tool for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

Benefits of using P&IDs:

- Improved communication between engineers, operators, and maintenance personnel

- Reduced errors in design and construction

- Increased safety and efficiency of plant operation

- Improved troubleshooting and maintenance

Tips for creating P&IDs:

- Use a consistent set of symbols and conventions

- Make sure the diagram is clear and easy to read

- Include all relevant information, such as the process flow, piping, instrumentation, and equipment

- Review the diagram carefully before finalizing it

P&IDs are an essential tool for the design, construction, and operation of process plants. By following these tips, you can create P&IDs that are accurate, easy to read, and effective.

Piping and Instrumentation Diagrams

Piping and Instrumentation Diagrams (P&IDs) are essential tools for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

- Process Flow: P&IDs show the flow of process fluids through the plant.

- Piping: P&IDs show the piping that connects the equipment in the plant.

- Instrumentation: P&IDs show the instrumentation that is used to control the process.

- Equipment: P&IDs show the equipment that is used in the process.

- Symbols: P&IDs use a consistent set of symbols to represent different components of the plant.

- Legends: P&IDs include a legend that explains the symbols used in the diagram.

- Title Block: P&IDs include a title block that contains information about the diagram, such as the project name, the date, and the author.

- Review: P&IDs should be reviewed carefully before finalizing them.

These key aspects of P&IDs are all essential for ensuring that the diagram is accurate, easy to read, and effective. By following these aspects, you can create P&IDs that will help to improve communication between engineers, operators, and maintenance personnel, reduce errors in design and construction, increase safety and efficiency of plant operation, and improve troubleshooting and maintenance.

Process Flow

Process flow is an essential part of any piping and instrumentation diagram (P&ID). P&IDs are used to design, construct, and operate process plants, and they provide a clear and concise overview of the plant’s piping, instrumentation, and equipment. Process flow diagrams show the flow of process fluids through the plant, and they are essential for understanding how the plant operates.

Process flow diagrams are typically created using a software program. The program allows the user to create a diagram that is both accurate and easy to read. The diagram will typically include a legend that explains the symbols used in the diagram, a title block that contains information about the diagram, and a process flow diagram that shows the flow of process fluids through the plant.

Process flow diagrams are an essential tool for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

Piping

Piping is an essential part of any piping and instrumentation diagram (P&ID). P&IDs are used to design, construct, and operate process plants, and they provide a clear and concise overview of the plant’s piping, instrumentation, and equipment. Piping diagrams show the piping that connects the equipment in the plant, and they are essential for understanding how the plant operates.

Piping diagrams are typically created using a software program. The program allows the user to create a diagram that is both accurate and easy to read. The diagram will typically include a legend that explains the symbols used in the diagram, a title block that contains information about the diagram, and a piping diagram that shows the piping that connects the equipment in the plant.

Piping diagrams are an essential tool for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

For example, in a chemical plant, the piping diagram will show the piping that connects the reactors, the distillation columns, and the other equipment in the plant. The diagram will also show the valves, pumps, and other components that are used to control the flow of process fluids through the plant.

Piping diagrams are an essential tool for the safe and efficient operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to prevent accidents and ensure the smooth operation of the plant.

Instrumentation

Instrumentation is an essential part of any piping and instrumentation diagram (P&ID). P&IDs are used to design, construct, and operate process plants, and they provide a clear and concise overview of the plant’s piping, instrumentation, and equipment. Instrumentation diagrams show the instrumentation that is used to control the process, and they are essential for understanding how the plant operates.

Instrumentation diagrams are typically created using a software program. The program allows the user to create a diagram that is both accurate and easy to read. The diagram will typically include a legend that explains the symbols used in the diagram, a title block that contains information about the diagram, and an instrumentation diagram that shows the instrumentation that is used to control the process.

Instrumentation diagrams are an essential tool for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

For example, in a chemical plant, the instrumentation diagram will show the instrumentation that is used to control the temperature, pressure, and flow of process fluids. The diagram will also show the alarms and other safety devices that are used to protect the plant and its personnel.

Instrumentation diagrams are an essential tool for the safe and efficient operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to prevent accidents and ensure the smooth operation of the plant.

Equipment

Equipment is a critical component of any piping and instrumentation diagram (P&ID). P&IDs are used to design, construct, and operate process plants, and they provide a clear and concise overview of the plant’s piping, instrumentation, and equipment. Equipment diagrams show the equipment that is used in the process, and they are essential for understanding how the plant operates.

- Process Equipment: Process equipment is the equipment that is used to carry out the chemical or physical processes that are required to produce the desired product. Examples of process equipment include reactors, distillation columns, and heat exchangers.

- Piping and Instrumentation: Piping and instrumentation are used to connect the process equipment and to control the process. Piping is used to transport process fluids, and instrumentation is used to measure and control the temperature, pressure, and flow of process fluids.

- Utilities: Utilities are the equipment that is used to provide the necessary support services for the process plant. Examples of utilities include boilers, cooling towers, and electrical generators.

- Safety Equipment: Safety equipment is the equipment that is used to protect the plant and its personnel from accidents. Examples of safety equipment include fire alarms, sprinkler systems, and emergency shut-off valves.

Equipment diagrams are an essential tool for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

Symbols

Symbols are an essential part of any piping and instrumentation diagram (P&ID). P&IDs are used to design, construct, and operate process plants, and they provide a clear and concise overview of the plant’s piping, instrumentation, and equipment. Symbols allow engineers and other professionals to communicate the design of a process plant in a clear and concise manner.

- Standardization: Symbols help to standardize the design of process plants. By using a consistent set of symbols, engineers can easily understand the design of any process plant, regardless of who designed it or where it is located.

- Clarity: Symbols help to make P&IDs more clear and easy to read. By using a consistent set of symbols, engineers can quickly identify the different components of a process plant and understand how they are connected.

- Accuracy: Symbols help to ensure the accuracy of P&IDs. By using a consistent set of symbols, engineers can reduce the risk of errors in the design of process plants.

- Communication: Symbols help to facilitate communication between engineers and other professionals. By using a consistent set of symbols, engineers can easily communicate the design of a process plant to other engineers, operators, and maintenance personnel.

Symbols are an essential part of P&IDs. They help to standardize the design of process plants, make P&IDs more clear and easy to read, ensure the accuracy of P&IDs, and facilitate communication between engineers and other professionals.

Legends

Legends are an essential part of any piping and instrumentation diagram (P&ID). P&IDs are used to design, construct, and operate process plants, and they provide a clear and concise overview of the plant’s piping, instrumentation, and equipment. Legends help to explain the symbols used in the diagram, and they are essential for understanding how the plant operates.

- Standardization: Legends help to standardize the design of process plants. By using a consistent set of symbols, engineers can easily understand the design of any process plant, regardless of who designed it or where it is located.

- Clarity: Legends help to make P&IDs more clear and easy to read. By using a consistent set of symbols, engineers can quickly identify the different components of a process plant and understand how they are connected.

- Accuracy: Legends help to ensure the accuracy of P&IDs. By using a consistent set of symbols, engineers can reduce the risk of errors in the design of process plants.

- Communication: Legends help to facilitate communication between engineers and other professionals. By using a consistent set of symbols, engineers can easily communicate the design of a process plant to other engineers, operators, and maintenance personnel.

Legends are an essential part of P&IDs. They help to standardize the design of process plants, make P&IDs more clear and easy to read, ensure the accuracy of P&IDs, and facilitate communication between engineers and other professionals.

Title Block

The title block is an essential component of any piping and instrumentation diagram (P&ID). It provides important information about the diagram, such as the project name, the date, and the author. This information is essential for understanding the context of the diagram and for ensuring that it is used correctly.

The title block is typically located in the lower right-hand corner of the diagram. It contains the following information:

- Project name: The name of the project that the diagram is associated with.

- Date: The date that the diagram was created or last modified.

- Author: The name of the person who created or last modified the diagram.

In addition to this information, the title block may also include other information, such as the revision number of the diagram, the scale of the diagram, and the units of measurement that are used in the diagram.

The title block is an important part of any P&ID. It provides essential information about the diagram that is essential for understanding the context of the diagram and for ensuring that it is used correctly.

Review

Piping and instrumentation diagrams (P&IDs) are complex documents that require careful review to ensure accuracy and completeness. A thorough review can help to identify and correct errors, omissions, and inconsistencies that could lead to problems during construction or operation of the plant.

- Accuracy: P&IDs should be accurate in all respects, including the representation of the piping, instrumentation, and equipment in the plant. Errors in the P&ID can lead to errors in the construction or operation of the plant, which could have serious consequences.

- Completeness: P&IDs should be complete, including all of the necessary information to construct and operate the plant. Incomplete P&IDs can lead to delays and confusion during construction or operation, and can also pose a safety hazard.

- Consistency: P&IDs should be consistent with other plant documentation, such as the process flow diagram and the equipment list. Inconsistent P&IDs can lead to confusion and errors during construction or operation.

- Clarity: P&IDs should be clear and easy to read. Complex or cluttered P&IDs can be difficult to understand, which can lead to errors during construction or operation.

By following these guidelines, engineers can create P&IDs that are accurate, complete, consistent, and clear. This will help to ensure the safe and efficient construction and operation of the plant.

A piping and instrumentation diagram (P&ID) is a detailed diagram that shows the piping, instrumentation, and equipment in a process plant. P&IDs are used to design, construct, and operate process plants, and they are essential for ensuring the safe and efficient operation of these plants.

P&IDs typically include the following information:

- A legend that explains the symbols used in the diagram

- A title block that contains information about the diagram, such as the project name, the date, and the author

- A process flow diagram that shows the flow of process fluids through the plant

- A piping diagram that shows the piping that connects the equipment in the plant

- An instrumentation diagram that shows the instrumentation that is used to control the process

P&IDs are an essential tool for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

Here are some of the benefits of using P&IDs:

- Improved communication between engineers, operators, and maintenance personnel

- Reduced errors in design and construction

- Increased safety and efficiency of plant operation

- Improved troubleshooting and maintenance

P&IDs have been used for over 100 years, and they continue to be an essential tool for the design, construction, and operation of process plants.

FAQs on Piping and Instrumentation Diagrams (P&IDs)

Piping and Instrumentation Diagrams (P&IDs) are essential tools for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

Question 1: What are the benefits of using P&IDs?

Answer: P&IDs offer several benefits, including improved communication between engineers, operators, and maintenance personnel; reduced errors in design and construction; increased safety and efficiency of plant operation; and improved troubleshooting and maintenance.

Question 2: What information is typically included in a P&ID?

Answer: P&IDs typically include a legend that explains the symbols used in the diagram; a title block that contains information about the diagram, such as the project name, the date, and the author; a process flow diagram that shows the flow of process fluids through the plant; a piping diagram that shows the piping that connects the equipment in the plant; and an instrumentation diagram that shows the instrumentation that is used to control the process.

Question 3: Who uses P&IDs?

Answer: P&IDs are used by a variety of professionals involved in the design, construction, and operation of process plants, including engineers, operators, and maintenance personnel.

Question 4: What is the difference between a P&ID and a process flow diagram?

Answer: A process flow diagram shows the flow of process fluids through the plant, while a P&ID shows the piping, instrumentation, and equipment that is used to control the process.

Question 5: What are some tips for creating effective P&IDs?

Answer: Some tips for creating effective P&IDs include using a consistent set of symbols and conventions, making sure the diagram is clear and easy to read, including all relevant information, and reviewing the diagram carefully before finalizing it.

Question 6: What is the future of P&IDs?

Answer: P&IDs will continue to be an essential tool for the design, construction, and operation of process plants. As technology advances, P&IDs will likely become more sophisticated and integrated with other plant systems.

Summary: P&IDs are essential tools for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant. By understanding the basics of P&IDs, you can use them to improve communication, reduce errors, and increase the safety and efficiency of your plant.

Transition to the next article section: For more information on P&IDs, please refer to the following resources:

Conclusion

Piping and Instrumentation Diagrams (P&IDs) are essential tools for the design, construction, and operation of process plants. They provide a clear and concise overview of the plant’s piping, instrumentation, and equipment, and they can help to ensure the safe and efficient operation of the plant.

P&IDs are used by a variety of professionals involved in the design, construction, and operation of process plants, including engineers, operators, and maintenance personnel. They are an essential tool for communication between these professionals, and they can help to reduce errors in design and construction, and increase the safety and efficiency of plant operation.

As technology advances, P&IDs will likely become more sophisticated and integrated with other plant systems. However, they will continue to be an essential tool for the design, construction, and operation of process plants.

Youtube Video: